ARGENT LLC

American Recovery & GENeration Technologies

Eco-friendly

Sustainable

B2B

Innovative

ARGENT LLC

American Recovery & GENeration Technologies

Eco-friendly

Sustainable

B2B

Innovative

American Recovery & GENeration Technologies

Sustainable recycling of industrial waste with advanced technologies to reduce greenhouse gas emissions and protect the environment

“GLOBALLY, ONLY 9%

OF PLASTIC GETS RECYCLED”

Greenpeace

OF PLASTIC GETS RECYCLED”

Greenpeace

OUR MISSION

Why is it beneficial for your project?

ADVANTAGES

According to feasibility studies and investment analysis, ROI for conventional incineration plants is about 11-12 years.

ROI for ARGENT waste treatment facilities is 4-5 years

ARGENT solutions are based on pyrolytic gasification, requires nearly no oxygen in the process. That means there’s almost no emission. The involved high temperature gasification, under specific pressure, in lack of oxygen, limits CO2 formation and eliminates any possibility of furans and dioxins production.

Reduce emissions by up to 70%

Our facilities consume 80% less energy than conventional producers of construction materials. We have designed a water-free waste processing and recycling.

Energy efficiency

Our circular approach to industrial waste recycling and the technological solutions we have developed enable the complete elimination of old waste accumulated in landfills or produced by manufacturing, mining and energy production. We can then convert landfill sites into green spaces, parks and industrial complexes, while producing low-carbon by-products for the polymers, composites and building materials industries.

Our solution

Integration of best technologies for a zero-waste strategy

We take the way we treat industrial and municipal waste to a whole new level. Our solutions are powered by scientific research and cutting-edge engineering technologies.

Waste collection

Our core expertise is in providing quality and value to our partners/ clients for their waste disposal requirements. Our team has an extensive engineering and project implementation experience in the following industries:

- oil & gas, coal & tailings,

- petrochemicals,

- waste management,

- waste processing,

- waste-to-energy,

- nano-powder production,

- chemical engineering,

- prototype & project development.

Gasification

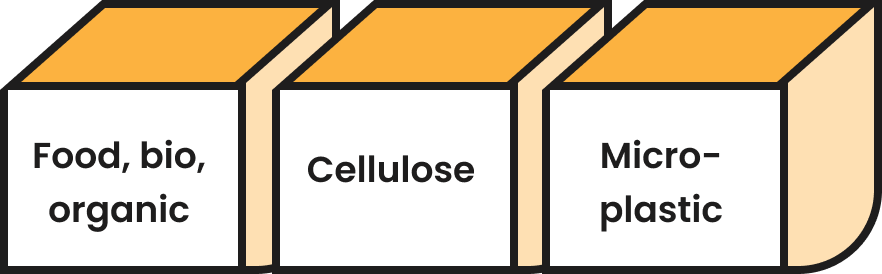

The residual, non-recyclable waste food, bio, organic, cellulose, and micro plastic) goes into a high-temperature gasification reactor. This final process has 3 stages:

1. Waste gasification with no furans or dioxins,

2. Clean electricity & heat generating,

3. Desalinated water by using residual heat (optional).

Here ends the waste life cycle, with a zero-waste reached goalt.

1. Waste gasification with no furans or dioxins,

2. Clean electricity & heat generating,

3. Desalinated water by using residual heat (optional).

Here ends the waste life cycle, with a zero-waste reached goalt.

Polymer granules

Most of the plastic waste is regenerated into recycled polymer granules via a thermo-chemical recycling process.

And

Sorting

Waste sorting is a key step in the recycling process. It requires advanced technological solutions adapted to the degree of depth, volume and sorting quality expected by the plant.

We are sorting more than 3 million tons of waste per year, and generate more than 20 recycled products. We know our job.

We are sorting more than 3 million tons of waste per year, and generate more than 20 recycled products. We know our job.

100%

Solid, liquid, glass, electronic/electrical, industrial, municipal, coal ash, mining waste or used tires can be transformed into a variety of products with commercial value:

Our finished products have a negative carbon footprint, in line with a circular economy model.

- Insulation materials (from construction and municipal waste)

- Admixtures for green cement, low-carbon concrete binders and aggregates

- Non-ferrous metal powders (from electronic/electrical scrap, construction waste)

- Petrochemicals (from hydrocarbon waste)

- Paper (from industrial and municipal waste)

- Polymer pellets and composites (from 100% plastic waste)

- Electricity and heat (from RDF/SRF/used tires)

Our finished products have a negative carbon footprint, in line with a circular economy model.

ABOUT

Industrial integrator providing turnkey solutions for municipal and industrial waste treatment by innovating in low-carbon mechanical, bio-based chemical and thermal technologies.

ARGENT processes solid and liquid waste into products with a negative carbon footprint and clean energy.

What we do

Research and develop waste sorting and recycling processes. We implement solutions for what most companies call “too-hard-to-recycle” materials and generate clean energy

How we do it

Since 2014, we focus on high temperature gasification, mechanical and

thermo-chemical recycling methods. Our waste recycling methods perfectly complies with “zero-waste” policy and a circular economic model.

Why we do it

To minimise the environmental footprint, to stop pollution of ecosystem and generate clean energy for our and future generations

1342 Military Road, PMB 960597, Niagara Falls, NY 14304

Address

Email

Tel

Contact us